Dust Extractor Vs Shop Vac Fundamentals Explained

Wiki Article

Dust Extractor Vs Shop Vac - The Facts

Table of ContentsSome Of Dust Extractor Vs Shop VacNot known Facts About Dust Extractor Vs Shop VacSome Known Incorrect Statements About Dust Extractor Vs Shop Vac The smart Trick of Dust Extractor Vs Shop Vac That Nobody is Talking AboutThe Definitive Guide for Dust Extractor Vs Shop VacOur Dust Extractor Vs Shop Vac PDFs

The obstacles for foundry dust collection systems rotate around crystalline silica dust, carbon monoxide gas, and warm, which are toxic combinations. These factors make meeting air quality standards challenging as well as demanding. For that reason, when selecting a dust control system for a foundry, the very first consideration is the capacity of the unit to stand up to harsh and harmful office problems.Other than the obvious conditions, the chosen devices needs to satisfy the laws of OSHA, the EPA, and also the NFPA. To meet those criteria, dirt collection systems use shakeout units, collection hoods, thaw, mold and mildew putting, cooling down hoods, as well as exhaust heaps. Pleated bag and also cartridge-style enthusiasts have a very reliable purification system along with a portable size as well as minimized pressure decrease.

Dust collection systems for this type of procedure need to be particularly made to fit the kind of finish being applied. The purpose of the system is to regulate as well as reduce overspray as well as dust.

Little Known Questions About Dust Extractor Vs Shop Vac.

It would appear likely to raise airflow and also movement, this type of remedy may be ineffective as well as waste power. The design of the cubicle relies on the force of the air getting in the cell or booth. For many systems, it is very important to have a mild vacuum in the cubicle to prevent feasible favorable pressure.One more approach is simply putting the make-up air connection on the top of the booth. No matter of the layout, it is necessary for the cleaning of the air to have cross air flow. Similar to a cleanroom, air flow in a thermal spray cubicle can be either straight or downward, though the descending design is best for dust collection systems. dust extractor vs shop vac.

The pharmaceutical market is an extremely controlled industry with comprehensive and specific guidelines. Dirt from drugs is produced mostly throughout the manufacturing and also product packaging of items - dust extractor vs shop vac. Each action of producing a medicine, which includes granulating, drying, mixing, pressing, finish, and also grinding, generates big quantities of dust that require to be gotten rid of.

The Single Strategy To Use For Dust Extractor Vs Shop Vac

HEPA filters are typically found in pharmaceutical dirt control systems given that they are one of the most effective and also reliable. Similar to a shop system, they are set up as an additional protection to achieve absolutely no exhausts. my link Reusing creates a terrific offer of dust as an all-natural result of decreasing items to their raw materials.

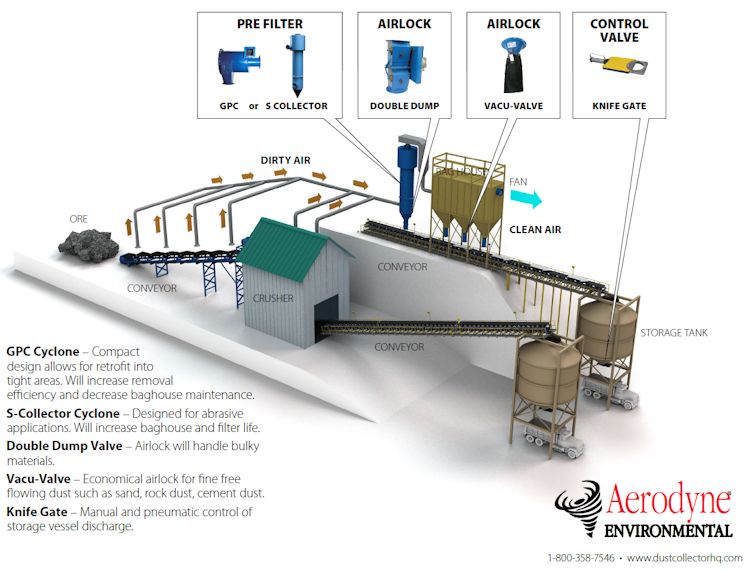

Dirt comes from after materials are shredded, squashed, or have paint or lacquer got rid of. All recycling centers are needed to stick to air quality criteria. As they work to meet top quality requirements and control toxins, they have identified that dirt control is a major problem, causing the broad use dirt collection systems to mitigate and also include the trouble.

Not known Facts About Dust Extractor Vs Shop Vac

When makers pick a dust control system, they are encouraged by manufacturers about the kind of system that would best fit their demands since buying as well as mounting a dust control system is a major investment. Particle issue comes in a large selection of kinds, from silicon dirt to wood chips as well as sawdust.Below is a list of the kinds of particles that dust collection systems can remove. Gypsum Plaster calls for a high-efficiency baghouse system with the ability of running at temperatures near 428 F (220 a knockout post C). Felt Felt is used in apparel production and needs dirt collection systems at 3 phases of the procedure.

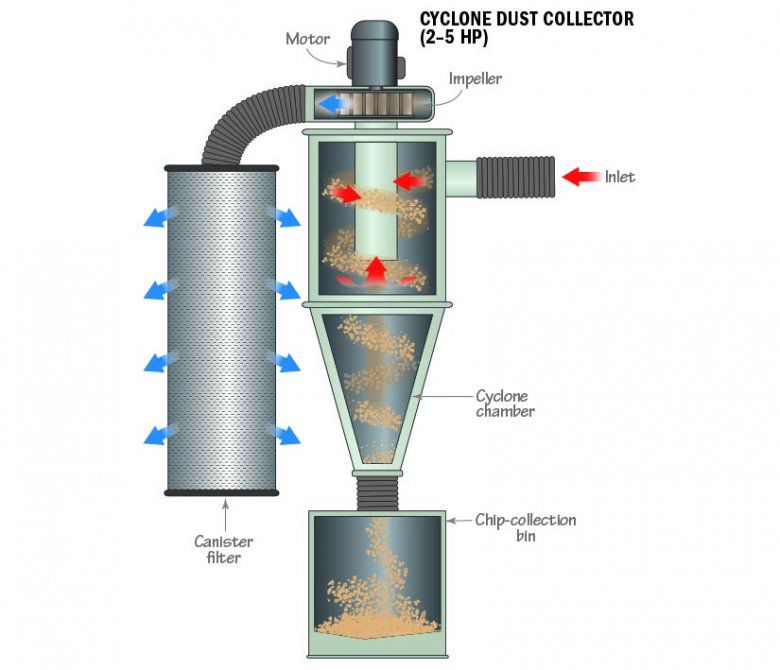

Sawdust This is the most common material gotten rid of by dirt collection systems. Cartridge or baghouse techniques can be used, with baghouse being the most reliable.

Rumored Buzz on Dust Extractor Vs Shop Vac

Textile filter bags in a cartridge system are the most reliable technique for collecting dirt. Cement Concrete dirt is produced throughout the motion and also transport of the item. Dust collection systems are covered to consist of the dirt and tidy the air. Clay Clay dust is created in the production of bricks.

With the intro of dirt collection systems, workers are safer as well as more safeguarded. Sugar Sugar dust is the byproduct of the production of Look At This sweet. Pulse jet systems are made use of to maintain the filters of the dust collection system particulate-free. The gathered material is eliminated and also gathered in drums. Zinc Zinc dirt is produced in the galvanizing process.

How Dust Extractor Vs Shop Vac can Save You Time, Stress, and Money.

A baghouse system is the recommended system. Rice Dust Rice dust has very fine as well as minute bits that collect throughout the manufacturing of rice-based items. A dirt collection system is needed for the defense and also safety and security of employees. Silica Silica is one of the most common substances on earth. It is a central part of a number of production operations, such as the production of glass, ceramic tile, cement, and asphalt.Report this wiki page